Gas Freeing Fans.

Victor Marine Ltd are specialists in the design and manufacture of portable Gas Freeing Fans offering both water driven and air driven systems. Manufactured to incorporate design features our fans lead the industry on quality & performance.

Our Product

Gas freeing on-board ships is carried out for various reasons

including but not limited to; change of cargo, health and safety and tank maintenance. It is essential that this is carried out efficiently and safely. Victor Marine’s range of fans competently achieve these aims and are well respected in the marine market.

Type approvals by:

Our Range

The wide range of portable and fixed tank cleaning machines on offer from

Victor Marine are all available with various styles of down tubes and hoses.

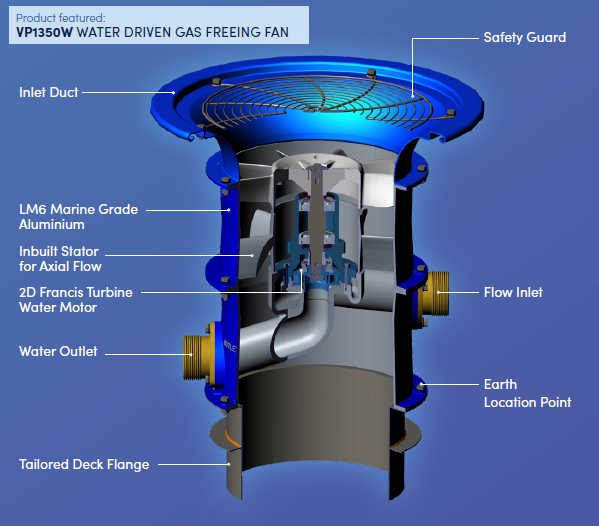

2D Francis Turbine

2D Francis Turbine Water Motor Runner installed in VP1350 and VP800.

- Efficiently converts flow/ pressure energy into kinetic energy via highly refined 2D flow geometry

- Robust and vibration reducing design ensures long fan lifetimes with minimal maintenance without compromising fan power

3D Francis Turbine

3D Francis Turbine Water Motor Runner Installed in VP1500W, VP1000W, VP1400W and VP700W

- Higher Efficiency

- Designed in-house and powered by VM’s innovative and efficient 3D Francis turbine, the VP1500 series fans reduce water consumption by 15% compared to conventional turbines, with no compromise on power and airflow throughput.

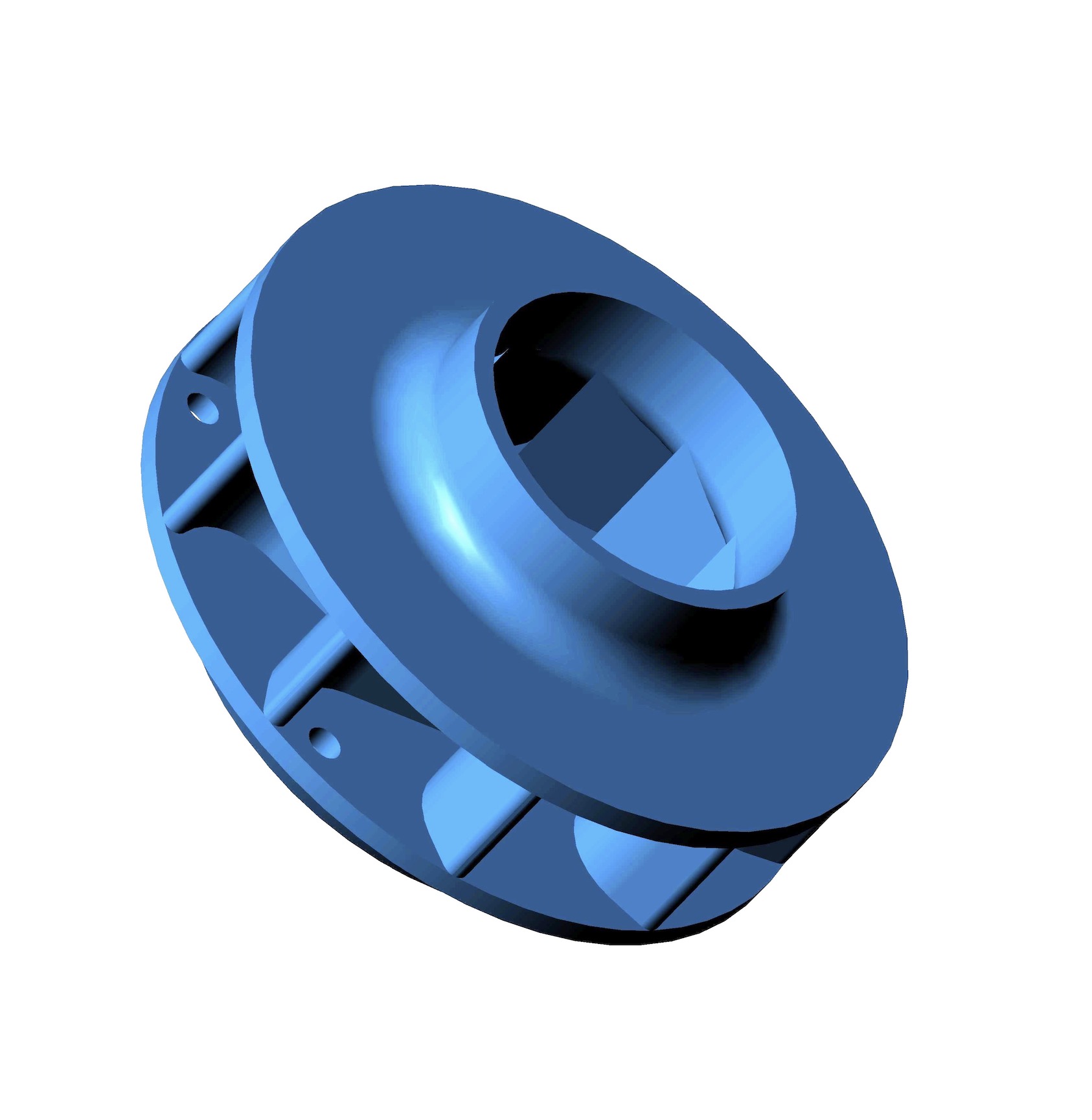

Aluminium Impeller

The VP 1350 and VP 800 have anti spark aluminum impeller blades designed to operate in hazardous and explosive atmospheres.

The aluminum is lightweight while offering durability in a vast range of environmental conditions.

Blade Profiles

VP1350 &VP800 – airfoil type designed for highest efficiency and low power consumption

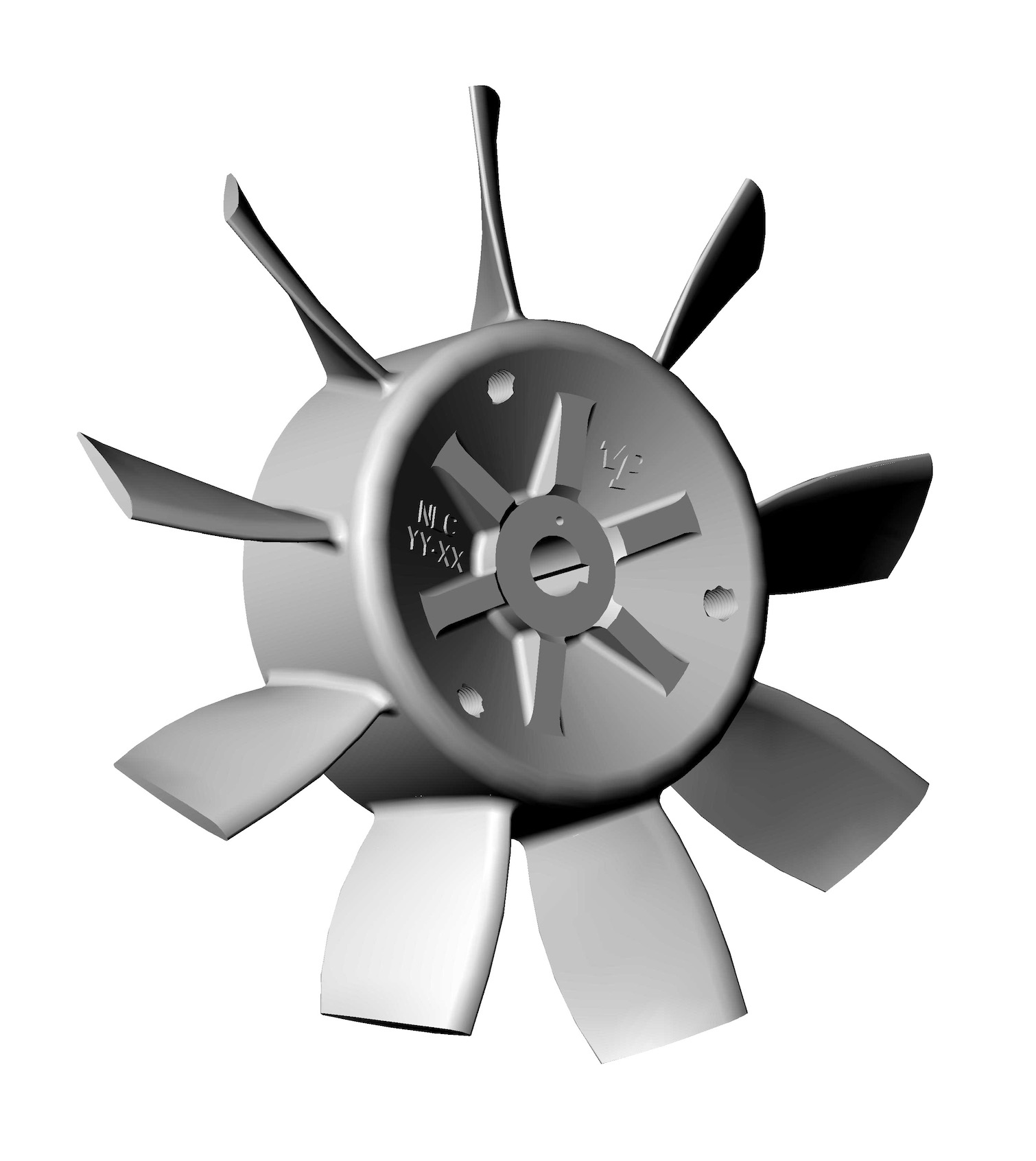

PAGAS Impeller

The VP1400 & VP700 have impeller blades made from PAGAS (an Anti-Static Glass Reinforced Polyamide) material capable of working in explosion proof conditions.

The PAGAS material is low weight, has a high tensile strength and is suitable in operating temperatures from -40°C to +110°C.

Blade Profiles

VP1400 & VP700 – Airfoil type designed for highest efficiency and low power consumption.

ATEX Approved Fans

- Use in Hazardous Areas

- Victor Marine design all fans to be able to work in explosive and hazardous conditions. All impellers, casings and motors are designed with compatible materials or with incorporated anti-spark tracks – in full accordance with the EC ATEX directive.

“Victor Marine Gas Freeing Fan equipment, marketed under its original and renowned Victor Pyrate brand name, is well established within the marine equipment market, noted for its quality, efficiency and reliability”

Product Ancillaries

Spares Kits

Supplied as basic (A) standard (B) or complete (C) or tune up kits. The kits include items required to overhaul the machines. Alternatively spares are available as individual items upon request.

Air Ducting & Flanges

Specially designed for marine ‘hazardous areas’, this is flame retardant and anti-static, heavy duty spiral wound PVC coated, flexible fabric ducting. Produced in standard 300mm diameter nominal bore or special purpose diameters and lengths, these ducts are suitable for both supply and exhaust mode operation. Various mild steel, stainless steel (AISI 316) and galvanised flanges to suit both deck opening and VP gas freeing fan outlet ducts are available.

All fans are supplied with a standard 318mm deck flange. Other deck flanges are available on request.

Layflat Hose Heavy Duty Supply (Red) and Medium Duty Exhaust (Blue)

Woven polyester reinforcement encased in polyurethane internal and external liner. Available in 38mm and 50mm nominal bore and a maximum length of 50 metres.

Connections and Spanners

We stock an extensive range of hose connections, hose couplings, hose spanners and deck valve adapters, mostly with BSP threads. Hose spanners are manufactured from a non-sparking alloy for complete safety.

Air Supply Hose (Black)

Neoprene rubber reinforced with multiple rayon braids. Available in 19mm and 25mm nominal bore.

Fan Trolley

Manufactured in a lightweight tubular construction, this trolley is available to ease transportation of the fans in restricted areas; complete with durable wheels and a fan retaining strap for added protection.

Speak to a specialist about your project requirements.

Our team of highly qualified engineers and technical sales have over 100 years collective experience in the marine industry, combined with a “Can Do” attitude when working with our customers to meet project specific regulations and compliance. From the smallest tug to the world’s largest FPSO, Victor are uniquely placed in the industry to help meet customer’s needs.

Design & Manufacturing

The designers at Victor Marine have a wealth of experience and industry knowledge. Customers can discuss their specific requirements for any project, and the development team will collaborate and create an innovative, bespoke solution.

Our comprehensive in-house engineering and testing facilities means we can design, manufacture and build many systems under our own roof. Victor Marine can also provide a range of shadow drawings, certification and process options.

Commissioning & Servicing.

Our range of Gas Freeing Fans & Tank Washing Equipment are designed to be installed and maintained by clients’ in house/on-board service teams.

Victor Marine Ltd can also offer engineers worldwide through our network of agents for all Commissioning and Servicing requirements. Our Agents & Engineers are fully qualified and trained to a high level on all of our products.