Oily Water Separators.

Victor Marine Ltd are specialists in the design and manufacture of Oily Water Separators and their accessories. Victor Marine systems are 5ppm approved, compliant with IMO regulation MEPC 107(49) and available in a range of sizes.

Our bilge oily water separators are specifically engineered for the marine industry, to maintain a cleaner marine environment, aiding the preservation of marine life throughout the world’s oceans and seas.

Our Product

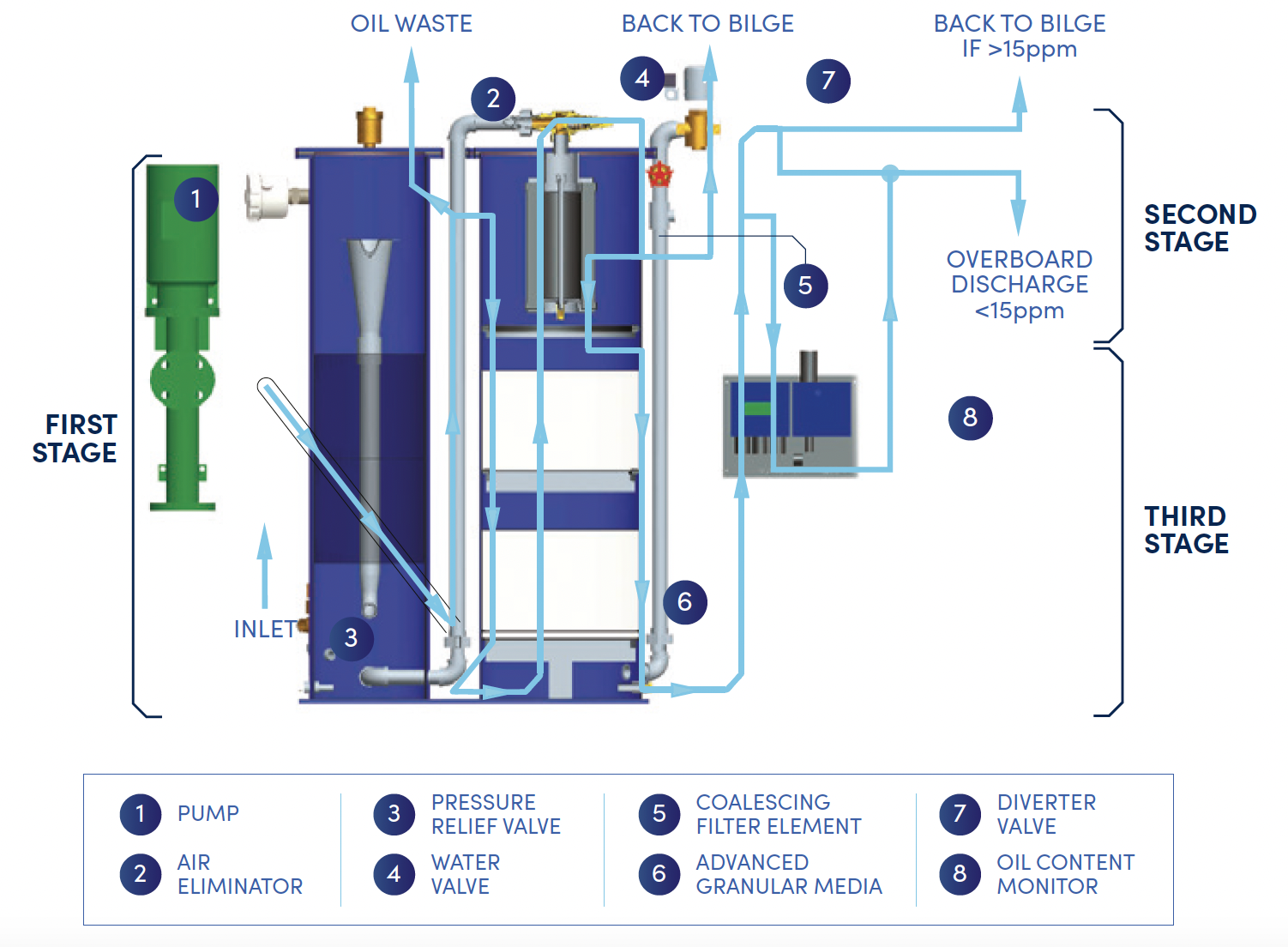

Victor Marine have been supplying systems for over 80 years and have installed over 7000 units. Combining their many years of experience and the latest technologies, Victor Marine have developed a range of oily water separators to separate oil from bilge water to the required international standard of 15ppm (parts per million) oil content before discharge overboard. Designed to ensure reliability, maintainability, affordability and compliance with the latest IMO regulation MEPC 107(49) The CS Series Oily Water Separator units are suitable for use on board vessels such as container & general cargo ships, chemical, VLCC, oil and product tankers, passenger and RO-RO ferries, workboats such as dredgers & tugs offshore support & service vessels, naval vessels & warships, cruise ships, superyachts and fast patrol craft, fi shing vessels, vessels for oil & gas such as FPSO, FLNG, FSU & LNG. Victor Marine has an in-house design team able to develop bespoke systems, for example, systems tailored for retrofitting in tight spaces, shock-mounted systems for naval standards, and low-magnetic signature systems for minesweepers, offshore rigs with ATEX requirements and onshore and offshore power stations.

Type approvals by:

Our Range

The compact CS Series is designed to fit the smallest engine rooms and is easy to install. Its three stage separation system and fully automatic operation is both effective and reliable, whilst making it easy to use and maintain.

The CS Lite is specifically engineered to be lightweight for use on vessels where the weight of a standard separator would be an issue e.g. fast attack craft and super-yachts. Constructed from marine-grade aluminium, this model offers a 30% weight saving over the standard CS Series model.

CS0500Lite

The lightweight version of our smallest CS500 unit for capacities required up to 0.5m3/hr. Specifically engineered to be lightweight for use on vessels where weight is as issue. Constructed from marine-grade aluminium giving a 30% weight saving over the standard CS500 and having low magnetic properties for vessels such as Minesweepers. Suitable for vessels up to 1600 GWT such as:

With over 100 years experience in oily water separation industry, Victor Marine’s bilge oily water separators are specifically engineered for the marine industry. Designed and tested to exceed the required international standard of 15 ppm under IMO regulation 107(49)

Product Ancillaries

Spares

All equipment is manufactured to the highest quality. Oily Water Separator spares are available worldwide and ex. stock. Recommended on-board spares kit includes Advanced Granular Media, Coalescer Set and Gasket Set.

Integrated Direct-on-Line Starter Control Panel – Multi-Voltage

Direct-on-Line pump motor starter installed in a mild steel polyester powered coated enclosure, protected to IP54, incorporating all necessary power supplies for the separator. The only shipboard supply required is the incoming power to the interlock isolator. All internal controls are 24V AC. Dry running protection & a fi rst stage vessel heater are included.

Dry Running Protection

The possible malfunction of a progressive cavity pump can be easily avoided by using dry running protection device. Preinstalled within the panel and pump. This is a recommended way to protect and prolong the life of your pump.

Shock Mount

Approved by the MoD for Naval use, these mounts were designed and developed primarily to protect delicate equipment against shock and vibrations to NSSII standards.

Low Level and High Level Switch

Small and lightweight, the bilge switch is extremely stable in non-static, highly contaminated liquids. It is designed for low or high level detection and can be wired into the OWS control panel to control automatic stop of the separator. The bilge switch is supplied with 2 metres of three-core SW4 marine-grade cable. It is a submersible fl oat type with slosh & debris shield to suit the bilge tank environment. It has an IP68 rating, can be pipe or wall mounted and has earned Class Type Approval.

Manual Three-Way L-Port Valve

Flanged cast iron three way valve to be used for in-port servicing and inspection. Refer to IMO MEPC 107(49) Section 6.1.1.

Inlet Pre-Strainer

Options available of a high quality simplex strainer complete with 60 mesh Stainless Steel basket filter or a cost effective Y strainer filter with 1mm mesh Stainless Steel screen. Both methods provide protection to the Oily Water Separator System.

Electronic Oil Record Book

The SMARTSAFE ORB Bilge Overboard Security System was developed to prevent vessels from illegal discharge “Magic Pipes” and minimise discrepancies in the oil record book. It is a complete interlocked system ensuring security of the discharges. The discharge data can also be used as an automated entry into an electronic ORB or interpreted and recorded in the Rivertrace Connected database providing a full auditable trail of the discharges.

Speak to a specialist about your project requirements.

Our team of highly qualified engineers and technical sales have over 100 years collective experience in the marine industry, combined with a “Can Do” attitude when working with our customers to meet project specific regulations and compliance. From the smallest tug to the world’s largest FPSO, Victor are uniquely placed in the industry to help meet customer’s needs.

Design & Manufacturing

The designers at Victor Marine have a wealth of experience and industry knowledge. Customers can discuss their specific requirements for any project, and the development team will collaborate and create an innovative, bespoke solution.

Our comprehensive in-house engineering and testing facilities means we can design, manufacture and build many systems under our own roof. Victor Marine can also provide a range of shadow drawings, certification and process options.

Commissioning & Servicing

Victor Marine Ltd offer engineers worldwide for all Commissioning and Servicing for our Oily Water Separator and Sewage Treatment Plants. Our engineers are fully qualified and trained to a high level on all of our products.