Sewage Treatment Plants.

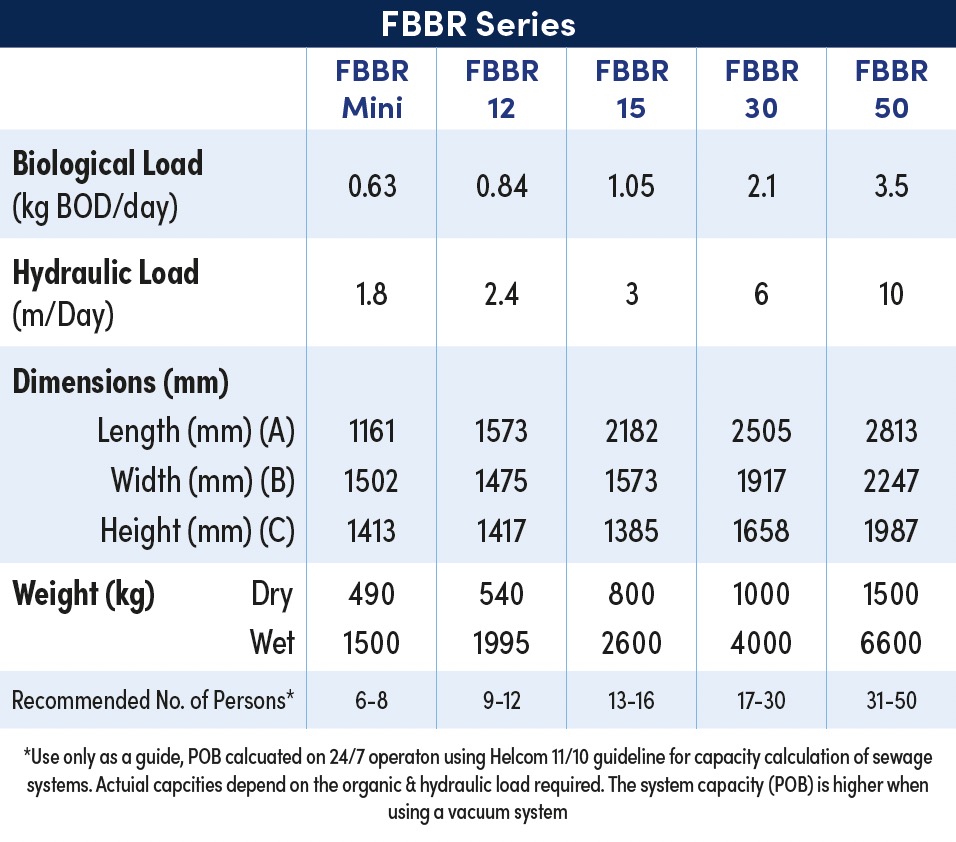

Victor Marine Ltd are specialists in the design & manufacture of FBBR (Fixed Bed Biofilm Reactor) biological sewage treatment plants. The units are available in a range of sizes and with accompanying accessories.

Our Product

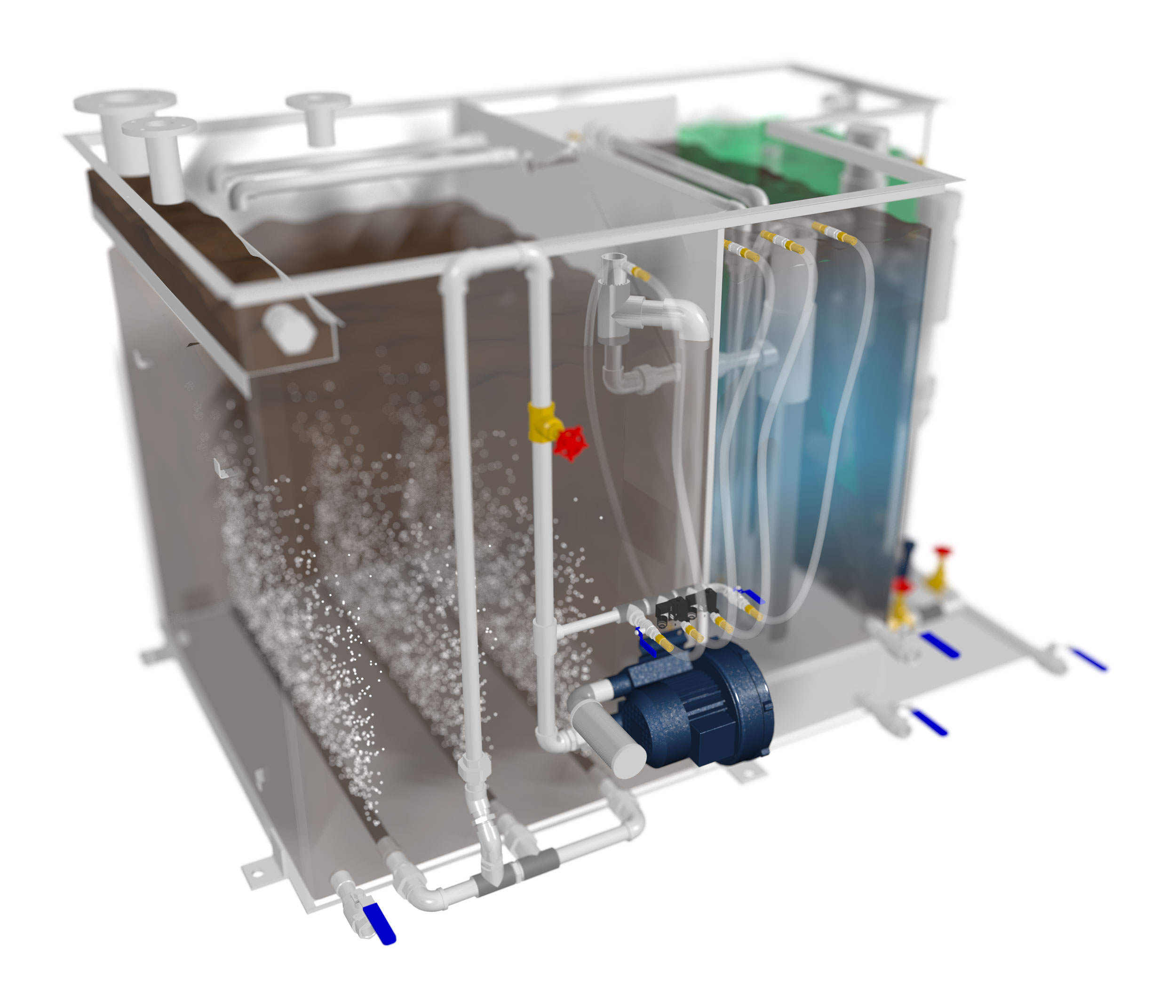

Victor Marine’s FBBR Series (Fixed Bed Bio Film Reactor) Biological Sewage Treatment Plant has been developed using the extremely well proven and compact fixed biofilm technology.

All equipment is manufactured to the highest quality. Sewage Treatment Plant spares are available worldwide and ex. stock. Recommended on-board spares include air filters, chlorine & dechlorine tablets, solenoids, gaskets and tank level switch.

Type approvals by:

How it Works

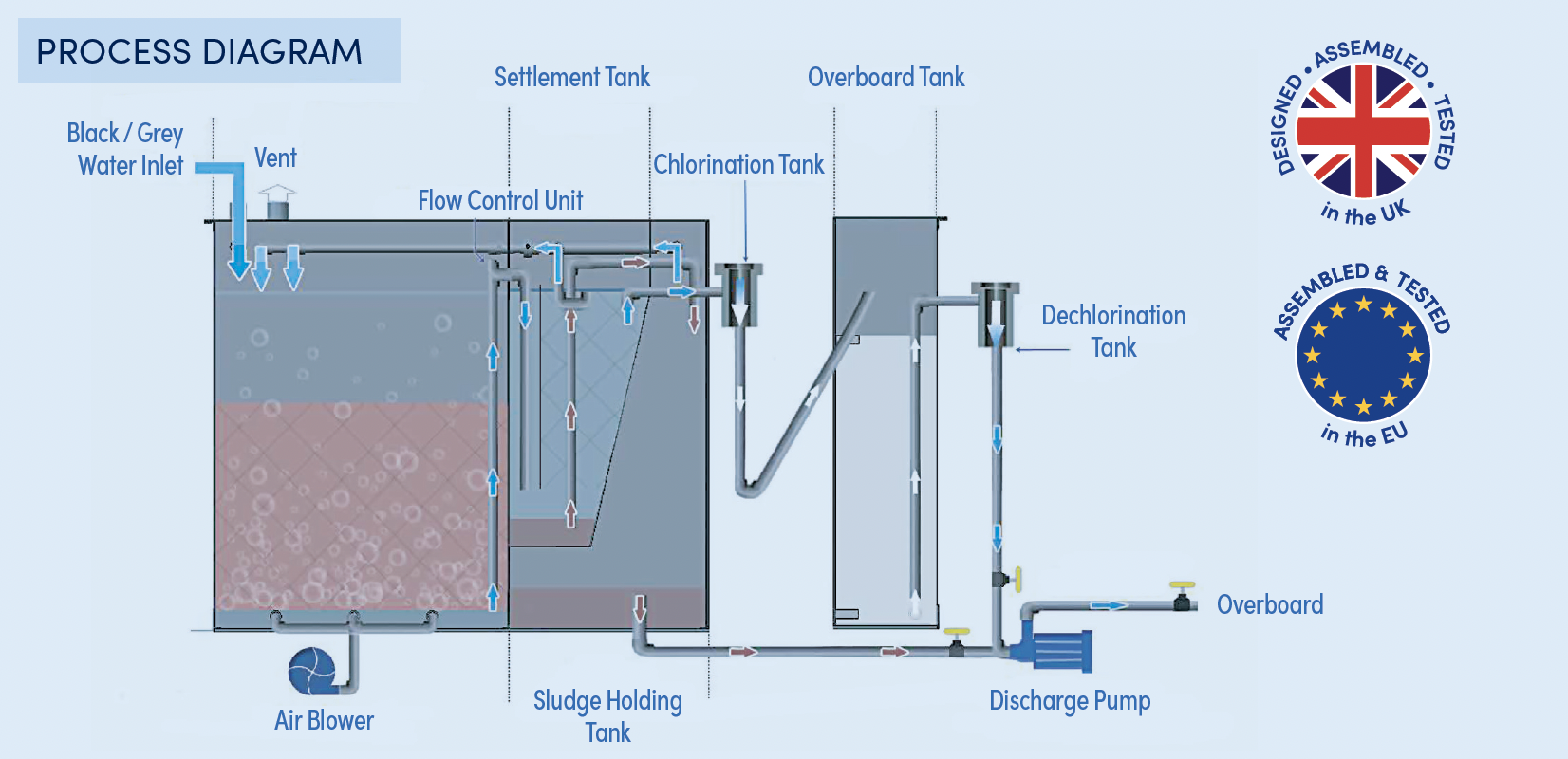

In the first stage, macerated* sewage is fed to the Bioreactor, an aerobic biological system, using a fixed structured inorganic media bed with very high specific surface area to allow bacterial growth. This ‘fixed bed’

system maximises the biomass volume, increasing the efficiency of the Bioreactor. It is also designed to direct the inflow sewage through an extended retention pattern to ensure maximum treatment and no bypass.

A low pressure aeration system provides the Bioreactor with a constant and uniform supply of oxygen to the biomass whilst preventing odours and hazardous gases from forming. The scoured biomass passes into the second stage via a Flow Control Unit (FCU) into the Settlement Tank. The FCU controls and stabilises the system during peak and low flows. The advanced settlement tank employs tube settlers and skimmers which magnify the settlement effect and also prevents disturbances caused by the

motion of the ship. Due to the increased efficiency, the settlement tank is smaller than conventional settlers whilst producing a clearer effluent and better results than the required IMO standard. Prior to overboard discharge, the effluent water is treated in the third stage, the Chlorination Unit. This is a

tablet dispensing unit which is both simple and easy to use, saving the engineer time when operating. Finally, during discharge overboard, the effluent is pumped into a dechlorination unit which removes any

excess chlorine, as per IMO requirements.

With over 100 years experience in the marine industry, Victor Marine’s sewage treatment plants are specifically engineered for the marine industry. Designed and tested to meet the latest IMO standard MEPC 227(64) and MEPC 159(55) All equipment is manufactured to the highest quality and spares are available worldwide through our network of agents.

Product Ancillaries

Spares Kit

All equipment is manufactured to the highest quality. Sewage Treatment Plant spares are available worldwide and ex. stock. Recommended on-board spares include air filters, chlorine & dechlorine tablets, solenoids, gaskets and tank level switch.

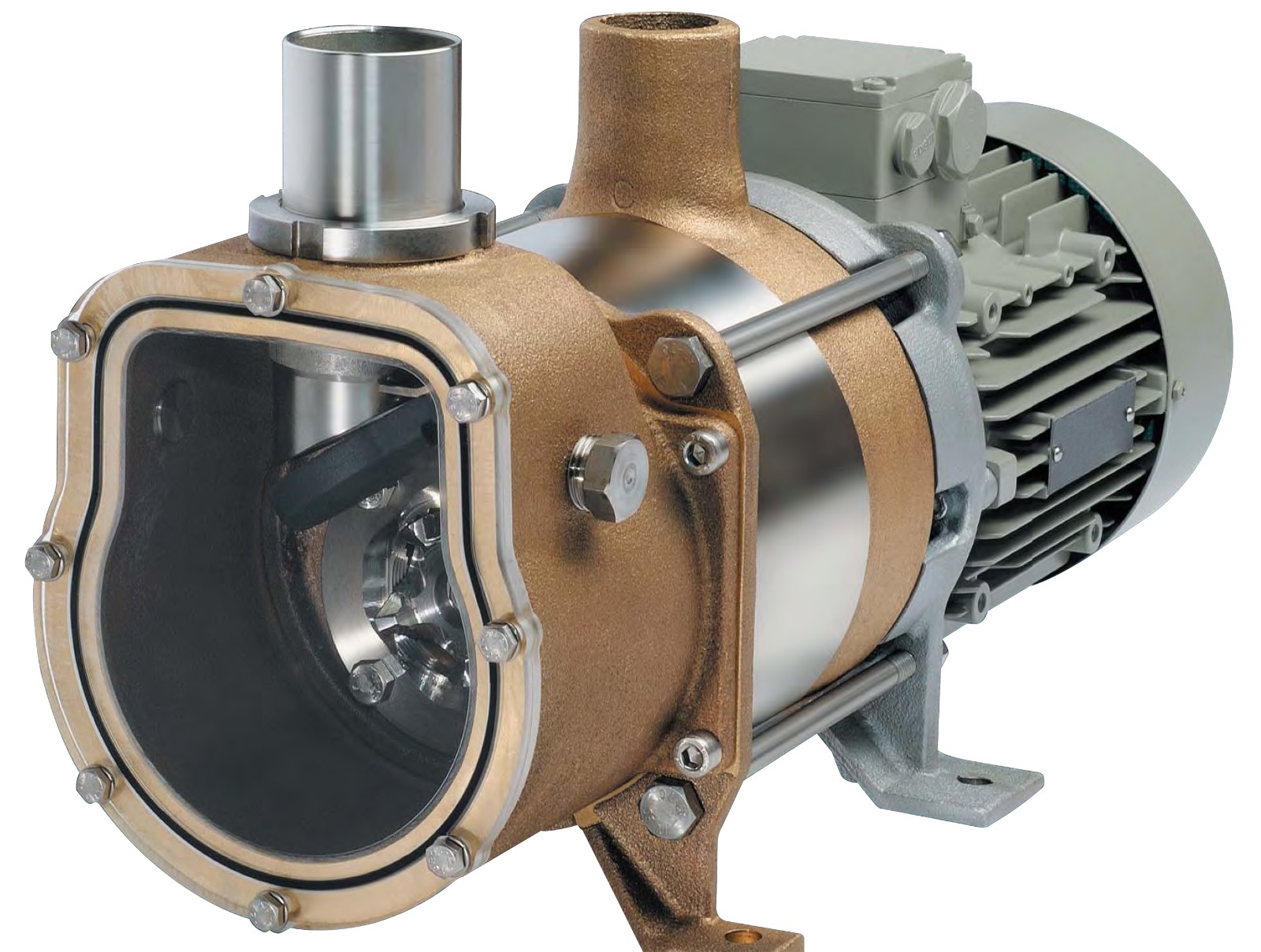

Stand-by Air Blower

The side channel air blower supplies air to the diffuser tubes in the bio zone. It has the added benefits of low noise operation, small size and a virtually maintenancefree design.

Grease Trap

Recommended by Victor Marine to be fitted in the galley for removal of fats, oils and greases (FOGs). Galley water must first pass through a Grease Trap before entering any wastewater tanks as FOGs can have an adverse effect on the pipework and sewage treatment plant. Victor Marine manufactures a range of sizes to suit customers’ requirements.

Vacuum Systems

We work in partnership with a global manufacturer and supplier of vacuum and waste management systems. We can provide solutions for global marine and municipal vacuum projects, specializing in vacuum toilets, food waste and dry waste systems.

We provide customers with timely and efficient service with our global agent and distributor network and the partnership enables us to provide a turkey package for sewage Treatment.

Speak to a specialist about your project requirements.

Our team of highly qualified engineers and technical sales have over 100 years collective experience in the marine industry, combined with a “Can Do” attitude when working with our customers to meet project specific regulations and compliance. From the smallest tug to the world’s largest FPSO, Victor are uniquely placed in the industry to help meet customer’s needs.

Design & Manufacturing

The designers at Victor Marine have a wealth of experience and industry knowledge. Customers can discuss their specific requirements for any project, and the development team will collaborate and create an innovative, bespoke solution.

Our comprehensive in-house engineering and testing facilities means we can design, manufacture and build many systems under our own roof. Victor Marine can also provide a range of shadow drawings, certification and process options.

Commissioning & Servicing

Victor Marine Ltd offer engineers worldwide for all Commissioning and Servicing for our Oily Water Separator and Sewage Treatment Plants. Our engineers are fully qualified and trained to a high level on all of our products.