Tank Washing Machines.

Victor Marine Ltd are specialists in the design and manufacture of Tank Washing Machines and their accessories. With nearly 70 years of experience in the supply of tank cleaning systems, our products have a proven track record of quality, efficiency & reliability.

Our Product

Tank Washing is a vital part of a ship’s operations and it is essential that the equipment on-board is robust, reliable and fit for purpose. Developing and manufacturing Tank Washing Equipment for nearly 70 years, Victor Marine has a wealth of knowledge and experience in providing tank cleaning solutions suitable for VLCCs to smaller product tankers and chemical carriers.

Type approvals by:

Our Range

The wide range of portable and fixed tank cleaning machines on offer from Victor Marine are all available with various styles of down tubes and hoses.

All machines are made in stainless steel to ensure durability and longevity. The internal gears and components are manufactured from high quality materials which ensure low wear and can operate under high pressures within a wide range of temperatures

VP Major

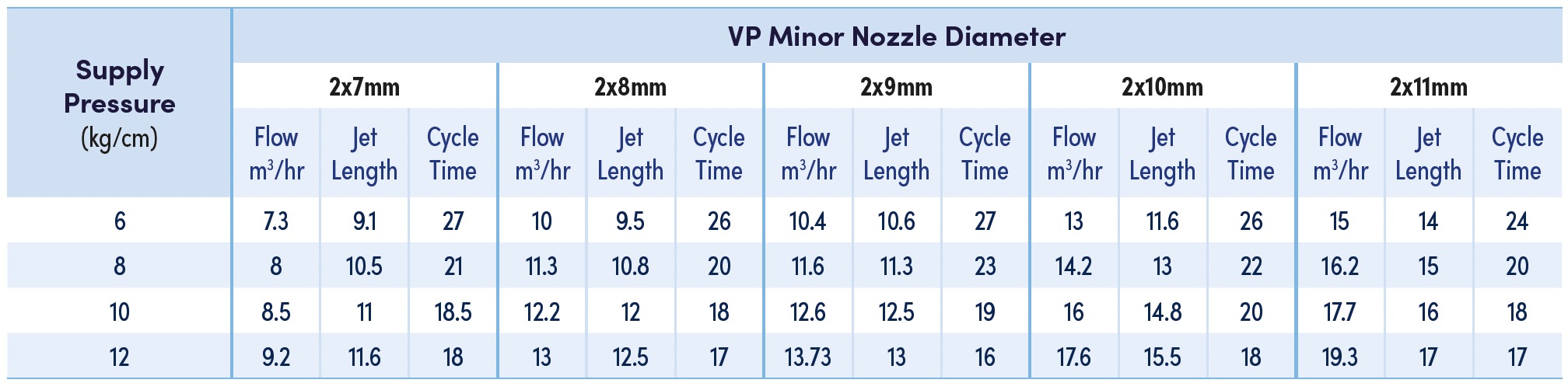

VP Minor

“Victor Marine’s Tank Washing equipment, marketed under the original established brand name of Victor Pyrate, are of proven high quality and are efficient, economical and robust”

Product Ancillaries

VP Major / Minor Spares Kits

Supplied as basic or standard kits. The kits include all major items required to overhaul the machines. Alternatively spares are available as individual items upon request.

Tank Washing Hose

Neoprene with styrene butadiene rubber (SBR) liner reinforcement with multiple rayon braids. Electrical continuity is ensured by twin braided stainless steel wires. All hoses are fully tested prior to despatch. Available in 38mm and 50mm nominal bore and a maximum length of 50 metres.

Hose Saddle

For easy handling and longevity of tank cleaning hoses, this lightweight, epoxy coated aluminium alloy hose saddle comprises of a saddle, deck plate, hose guide and positioning clamp. Optionally, there is a choice of base plate sizes and materials – standard size 318mm.

Optionally, there is a choice of base plate sizes and materials – standard size 318mm.

Weight: 7kg

VP Watergun

A powerful water gun with effective jet lengths of up to 25m with a low recoil for rapid cleaning of decks and bulk cargo holds. Supplied complete with a tripod stand, the lightweight design is ideal for one-person operation.

Connections & Spanners

We stock an extensive range of hose connections, hose couplings, hose spanners and deck valve adapters, mostly with BSP threads. Hose spanners are manufactured from a nonsparking alloy for complete safety.

VP Tripod

Marine grade aluminium tripod to aid in the lifting of tank washing machines in and out of deck openings. Sizes available on request.

Mounted Tank Washing Machine

Speak to a specialist about your project requirements.

Our team of highly qualified engineers and technical sales have over 100 years collective experience in the marine industry, combined with a “Can Do” attitude when working with our customers to meet project specific regulations and compliance. From the smallest tug to the world’s largest FPSO, Victor are uniquely placed in the industry to help meet customer’s needs.

Design & Manufacturing

The designers at Victor Marine have a wealth of experience and industry knowledge. Customers can discuss their specific requirements for any project, and the development team will collaborate and create an innovative, bespoke solution.

Our comprehensive in-house engineering and testing facilities means we can design, manufacture and build many systems under our own roof. Victor Marine can also provide a range of shadow drawings, certification and process options.

Commissioning & Servicing

Our range of Gas Freeing Fans & Tank Washing Equipment are designed to be installed and maintained by clients’ in house/on-board service teams.

Victor Marine Ltd can also offer engineers worldwide through our network of agents for all Commissioning and Servicing requirements. Our Agents & Engineers are fully qualified and trained to a high level on all of our products…